Replacing Old Tower Packing

Replacing Old Tower Packing

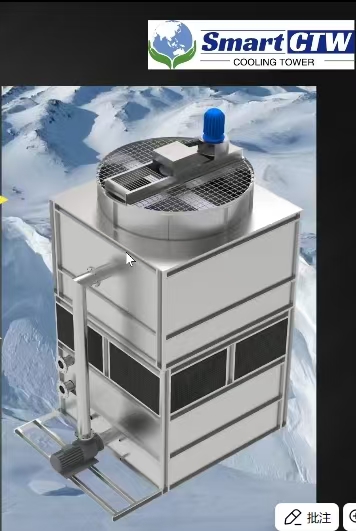

Product Details

After a certain period of service, the packing inside a cooling tower, exposed to high temperature, high humidity, and corrosive substances, gradually ages, becomes brittle, deforms, and even cracks. The hydrophilic layer on the surface of the aged packing sheds, and the water film becomes a stream, reducing the water-air contact time and the heat dissipation capacity. Aged packing fragments can enter the condenser copper tubes with the water flow, causing blockage. In severe cases, this can require downtime for maintenance. Inorganic salt crystals, silt, and algae in the circulating water deposit on the packing surface, blocking water flow channels and air gaps, reducing the heat exchange area. This significantly reduces the temperature difference (for example, a designed temperature difference of 5°C may only be 2-3°C in reality), and cooling efficiency drops by more than 20%. At this point, the cooling tower packing should be replaced promptly.

A total of 1 page 1 data