Smart's Falling Film Heat Exchange Counterflow Closed Cooling Tower Launches

August 26, 2025, marked a milestone in China's cooling technology reaching new heights. Smart's independently developed falling film heat exchange counterflow closed cooling tower officially began operation and was officially launched. The successful application of falling film heat exchange technology in the cooling tower industry has achieved domestic substitution of this high-end cooling equipment, providing a new solution for energy conservation and consumption reduction in my country's industry.

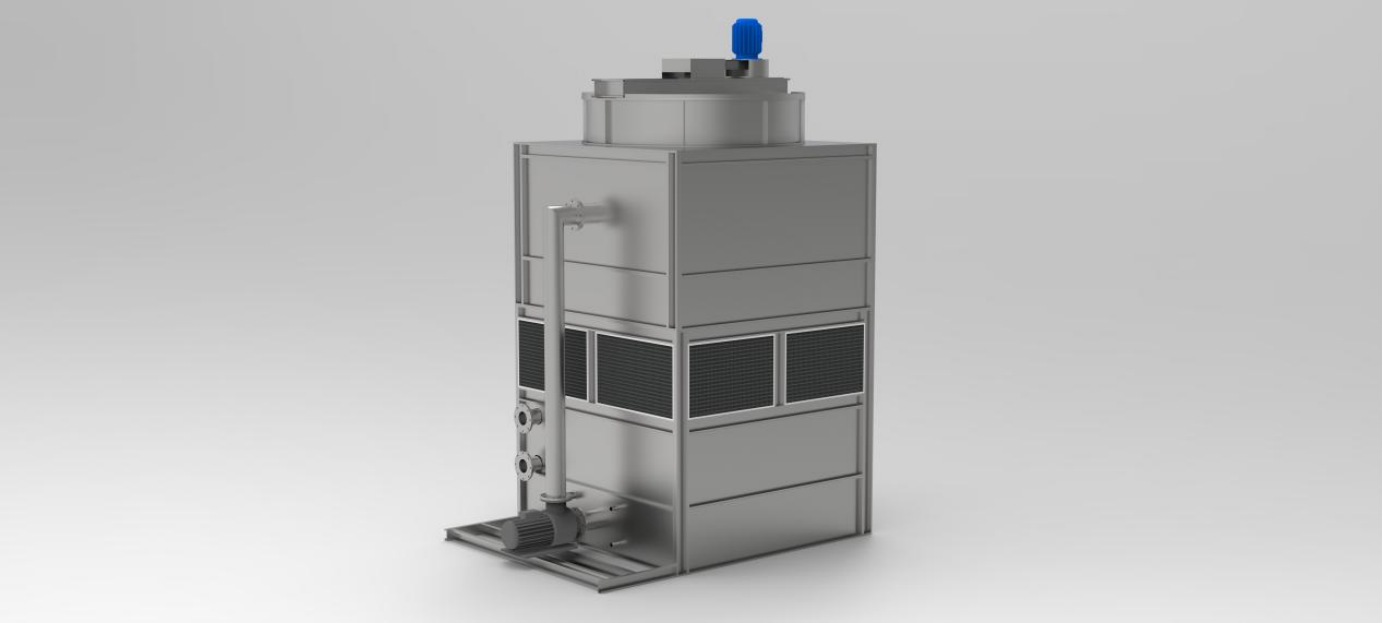

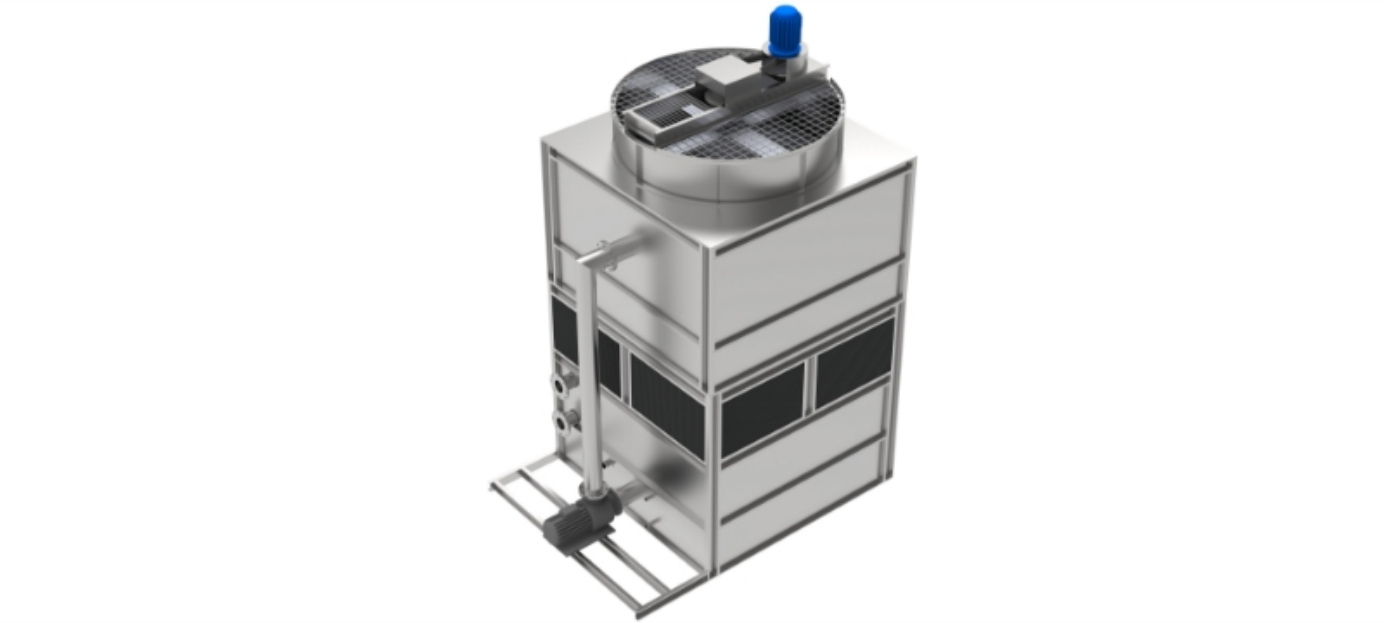

Product Appearance

Core Technology Principle

This product innovatively combines falling film heat exchange technology with a counterflow closed tower structure. Cooling water passes through a double-layer spray system, forming a uniform, stable water film on the outer surface of the heat exchange coil. The water flows downwards using gravity, effectively exchanging heat and mass with the cool air flowing upwards, achieving extremely high heat exchange efficiency.

Core Product Advantages and Technical Features

1. Highly Efficient Water Collection and Strong Environmental Adaptability

Tri-fold Multi-dimensional Inlet Grille (90mm Thick): Excellent water collection, completely eliminating water drift and ensuring a dry environment around the tower.

Algae and Sand Control: The grille design effectively blocks direct sunlight, inhibiting algae growth inside the tower and maintaining clean water quality. It also effectively prevents windblown sand from entering the northwest region, extending equipment life.

Highly Scalable: Can be expanded to a combined dry and wet operation mode, significantly saving operating water costs during dry and cold seasons.

2. Innovative Double-Layer Water Distribution for More Efficient Falling Film Heat Exchange

First Layer (Main Spray): Utilizes ABS double-layer high-temperature nozzles for uniform spraying, high-temperature and corrosion resistance, and ensures precise initial water distribution.

Second Layer (Secondary Water Distribution): Innovative open-tower basin-style nozzles provide secondary distribution of low-temperature water from the filler, forming a perfectly even water film covering the coil surface.

Dry-Spot Design: Since the coils are not fed by air, water distribution relies entirely on gravity, resulting in zero dry spots in the water film. This significantly improves heat exchange efficiency and provides superior cooling performance.

3. Extra-Large Packing for Deep Cooling

The packing volume and heat exchange area far exceed those of conventional countercurrent closed towers (over 1.5 times), significantly reducing spray water temperature and providing a cooler cooling medium for the coils, ultimately achieving better overall cooling performance.

4. Optimized Structure for Energy Saving and Noise Reduction

Reduced Air Resistance: The coils are positioned downward, significantly reducing air resistance.

Lower Energy Consumption: The fan-motor power consumption ratio is low, resulting in more energy-efficient operation.

Quieter Operation: The single belt-driven fan structure achieves low speed and significantly reduces operating noise.

5. Easy Maintenance and User-Friendly Design

·All key accessories, including the float valve, water supply system, and spray pump, are located outside the tower, allowing for inspection and maintenance without entering the tower, significantly reducing O&M complexity and costs.

6. Lowered Center of Gravity for Stable Operation

The entire cooling coil adopts a sunken design, effectively lowering the tower's overall center of gravity, enhancing structural stability and wind resistance, and ensuring safer and more reliable operation.

7. Splash and Ice Prevention for Year-Round Safety

Water baffles installed at key locations direct the spray water toward the center, effectively preventing ice from forming on the air inlet grille during winter and splashing during summer, ensuring stable all-weather operation.

8. Diverse Materials, Customizable

The standard configuration features high-performance SUS304 stainless steel heat exchange coils. A variety of material options, including copper and galvanized steel, are also available to meet the needs of various industries, budgets, and corrosive environments.

Summary: Smart's falling-film heat exchange countercurrent closed cooling tower combines high-efficiency heat exchange, energy and water conservation, stability and reliability, and intelligent maintenance. Its successful launch is not only a technological breakthrough, but also provides a new green and economical cooling option for numerous energy-intensive industries, such as data centers, metallurgy, chemicals, intelligent computing, and new energy.

A total of 1 page 1 data