SmartCTW successfully delivered a cross-flow closed cooling tower to a well-known pharmaceutical company in Zhucheng, Shandong.

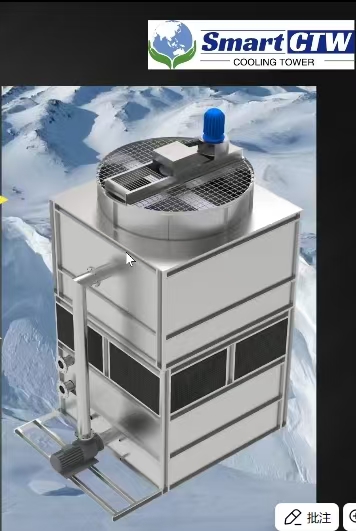

The standard SmartCTW SM-BH cross-flow closed cooling tower is constructed of galvanized steel and utilizes laser cutting and CNC bending processes, reducing welding while ensuring precise control of component processing and tolerances. It can be shipped in whole or in separate pieces, subject to transportation requirements, significantly reducing on-site construction time and uncontrollable risks. Steel components are double-layered with reinforced butyl strips and cooling tower-specific anti-aging sealant for leak prevention, eliminating the worry of leaks over extended use. The use of fiberglass (FRP) has been reduced or eliminated, significantly reducing environmental pollution and occupational health issues associated with its production and processing. It also mitigates environmental issues caused by non-degradable FRP during subsequent modifications and significantly reduces the risk of fire and poisoning during cooling tower assembly. The heat exchanger is constructed of SUS304 stainless steel (optionally available in 316L stainless steel or copper), which is corrosion-resistant, highly efficient, and resistant to clogging. The SM-BH cooling tower can ensure sufficient cooling efficiency, high stability and durability of the equipment. In addition, this model of cooling tower has passed the national standard

(1) Adopting new sheet metal processing technology to maximize production efficiency and reduce environmental pollution caused by the production process.

(2) The open water distribution system is easy to inspect and clean; (3) The single-chamber water tower motor adopts a multi-power design, which can be flexibly matched with different working conditions;

(4) Increasing water flow does not require significantly increasing the water pump pressure head;

(5) Parallel combination, small footprint;

(6) Minimizing on-site installation time;

(7) Standard stainless steel heat exchanger, taking into account both heat exchange efficiency and corrosion resistance.