Noise Optimization

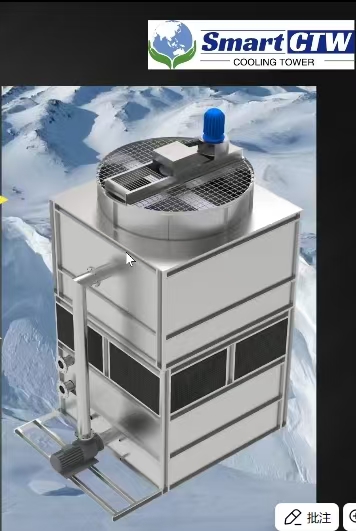

Product Details

The main sources of cooling tower noise are the fan's intake, exhaust, and deceleration noise during operation, water splashing noise, motor noise during operation, and noise radiated from the pump, piping, valves, and tower body. The following measures can be taken during the cooling tower design and selection phase: 1. Use a low-speed cooling tower fan. For a given processing capacity, the lower the fan speed, the quieter the fan. 2. Select silent fans and multi-blade fans. Impellers with wide chords and forward-swept blades reduce eddy currents, significantly reducing tip noise. Furthermore, increasing the number of blades increases blade projection solidity, allowing for lower operating speeds and thus lower fan noise. 3. Add variable frequency control. When system load decreases, the fan speed is adjusted by controlling the motor with a frequency converter, saving energy and reducing noise when full speed is not required. 4. Install a sump cover. Installing a sump cover reduces water impact noise. 5. Improve the packing installation position. When designing and installing the packing, immerse it below the liquid level in the sump to reduce the sound of the spray water falling into the sump. Old tower renovation measures: Add guide silencer ducts, soundproof covers, soundproof screens, and air intake and exhaust silencers.

A total of 1 page 1 data