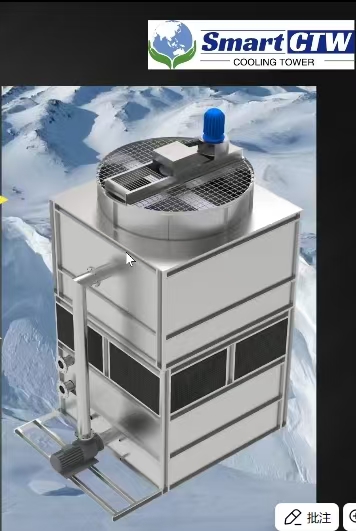

Compound flow closed cooling tower

Focusing on customized cooling tower manufacturing, SmartCTW shipped its first composite flow all-stainless steel closed cooling tower

Project location: overseas

Quantity: 4 systems (including cooling tower, full set of pipelines, integrated pump room)

Project difficulties: short delivery period, customized cooling tower, full set of water treatment pump room equipment unit, integrated automation instrument control, and pump group are all required to be electromagnetically shielded according to the foundation already made on site. The full set of equipment system is prefabricated in the workshop, and welding is not allowed on site. The stainless steel surface of the cabinet is all brushed stainless steel. All line ducts are prefabricated in the factory.

Material requirements: The shell and frame are all made of 3-5mm SUS304 stainless steel, and the heat exchanger is made of 316L thickened raw material. All pipelines are made of 304 stainless steel. All components such as the integrated pump room are made of 304 stainless steel. The tower top guardrail is required to use zebra pattern warning.

Smart has a professional design, production and installation team to meet the various customized needs of customers. It takes only one month to complete the manufacturing and commissioning and cooperate with customers to complete the statistics and packaging.

Water treatment integrated pump room (picture inside the container)

Water system pipelines and brackets (picture inside the container)

Cooling tower components (photo inside the container)

A total of 1 page 1 data