What is the difference between counterflow and crossflow cooling towers?

What is the difference between counterflow and crossflow cooling towers?

There are significant differences between counterflow and crossflow cooling towers in many aspects. Here is a detailed comparison of the two types of cooling towers:

Counterflow cooling tower

1. Structural form and size

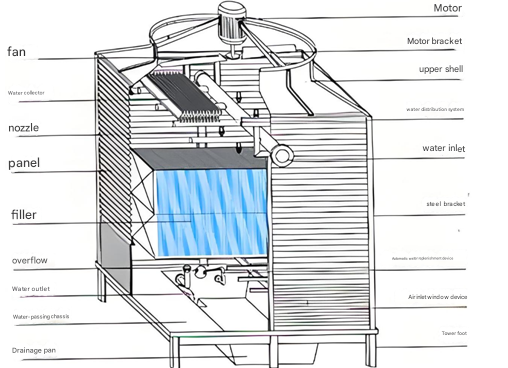

Counterflow cooling tower: Due to factors such as the height of the air inlet and the horizontal arrangement of the water collector, the total height of the counterflow tower is relatively high and the volume is large.

Crossflow cooling tower: The height of the packing is close to the tower height, and the water collector does not occupy the height, so the total height of the crossflow tower is relatively low and the volume is relatively small.

2. Water distribution system and water spraying density

Counterflow cooling tower: The water distribution system adopts nozzles, which has high requirements for the pressure head and the nozzles are easy to clog.

Crossflow cooling tower: The water distribution system adopts gravity natural fall, the water holes are not easy to clog, and the water distribution is uniform, which maximizes the performance of the packing.

3. Packing height and design flexibility

Counterflow cooling tower: The packing height is limited.

Crossflow cooling tower: The packing height can be infinitely high in theory, and the design flexibility is greater.

4. Overhaul and maintenance

Counterflow cooling tower: The entire tower body is a closed structure, and the equipment needs to be shut down for overhaul or daily maintenance.

Crossflow cooling tower: The tower body is equipped with an inspection door, and there is an inspection space inside the tower, so that the equipment can be inspected and maintained without stopping.

V. Airflow organization and resistance

Counterflow cooling tower: The proportion of exhaust air entering the recirculation is small.

Crossflow cooling tower: The air intake height is high, closer to the air inlet, the air recirculation ratio is high, and the impact on heat exchange efficiency is greater.

Crossflow cooling tower

VI. Noise level

Counterflow cooling tower: There is a large distance between the filler and the lower water tank. When the water falls from the filler, a loud sound of falling water is generated, and the noise is relatively high.

Crossflow cooling tower: A small part of the lower part of the filler is submerged in the water. After the water flows through the surface of the filler, it falls directly into the lower water tank, and the noise is relatively low.

VII. Water-saving and environmental protection

Counterflow cooling tower: The fan is located directly above the filler and the distance is relatively close. The floating water volume is large, and the splash loss of the water in the lower water tank is also large. It is easy to form water mist around the cooling tower, which is easy to cause the reproduction of Legionella bacteria.

Crossflow cooling tower: The fan is located in the middle of the cooling tower, and the filler is located on both sides, so the floating water volume is small and more environmentally friendly.

VIII. Application occasions

Counterflow cooling tower: The cooling water temperature is controlled more accurately, and it is suitable for occasions with high requirements for water temperature control.

Crossflow cooling tower: It is greatly affected by the air temperature, and the fan efficiency is relatively low, but it has the advantage of less space when multiple towers are used in parallel. Under the condition of the same thermal performance, the crossflow tower packing consumption is large but it is easy to clean.

In summary, there are significant differences between counterflow and crossflow cooling towers in terms of structure, water distribution system, packing height, inspection and maintenance, airflow organization and resistance, noise level, water saving and environmental protection, and application occasions. The choice of which type of cooling tower needs to be determined according to the specific use environment and needs.

A total of 1 page 1 data