Panel

The main material for cooling tower production is magnesium-aluminum-zinc steel plate (optional Z700 heavy galvanized steel plate, ordinary galvanized steel plate and SUS304 stainless steel plate), all of which are made of national standard materials without negative difference. Excellent anti-corrosion performance.

Main body

The frame is made of high-quality high-strength hot-dip galvanized steel, with an integral column design, supplemented by reasonably arranged beams and inclined devices to enhance the stability of the tower structure.

The design of the long-span beam has been carefully calculated and verified by professional designers, and the deflection value of the entire series is controlled within the standard reliable range.

Fan

A special fan for aluminum alloy/glass reinforced plastic is used, which undergoes dynamic and static balance tests before leaving the factory. The fan adopts a large air volume design, the fan angle is adjustable, and the fan noise meets the national standard noise requirements.

Motor

Adopts IP55 housing protection level, F-class insulation, B-class temperature rise special waterproof motor, maintenance-free except for normal refueling, reducing customer use and maintenance costs.

Transmission mode

The belt or gear reducer is used in combination, and the wear parts are cheap, and the use and maintenance costs are low. The reducer has high manufacturing precision, high transmission efficiency, low noise, long effective use period of the equipment, and convenient maintenance and repair.

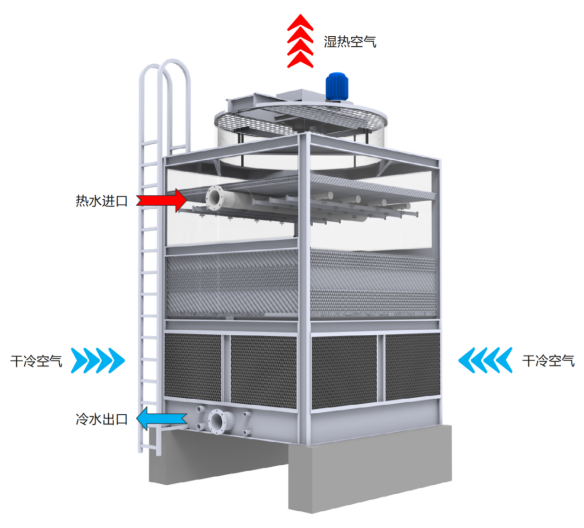

Air inlet grille

According to different use occasions, PVC or magnesium-aluminum-zinc plate is used to make air inlet grilles of different shapes, which are non-blocking, anti-direct sunlight, prevent algae reproduction, breeding microorganisms, and splash water.

Sprinkling filler

Using PVC raw materials, high heat exchange efficiency, reasonable texture water channel design, good hydrophilicity, uniform water film formed, not easy to block, low wind resistance coefficient, reasonable air-water ratio, adhesive installation, easy maintenance and replacement.

Anti-drifting measures

Effective water blocking measures are taken in the spraying area to ensure that the horizontal airflow will not interfere with the spraying water flow. The inlet and outlet of the filler have their own honeycomb-shaped combined edges, which are strictly designed according to the optimal economic wind speed. The air-water exchange flow characteristics are used to avoid the "splashing" phenomenon of sprinkler water and reduce drifting losses.

Water distribution system

The pool-type water distribution system, with variable flow nozzles, can effectively ensure the uniformity of water distribution.

Intelligent control (optional)

The control system integrates sensing technology, automatic control technology and information processing technology, and has water temperature monitoring, stepless automatic energy-saving operation, variable flow operation, anti-freezing operation, water quality monitoring, motor and fan monitoring functions, providing efficient, energy-saving and reliable operation guarantee for your cooling tower.