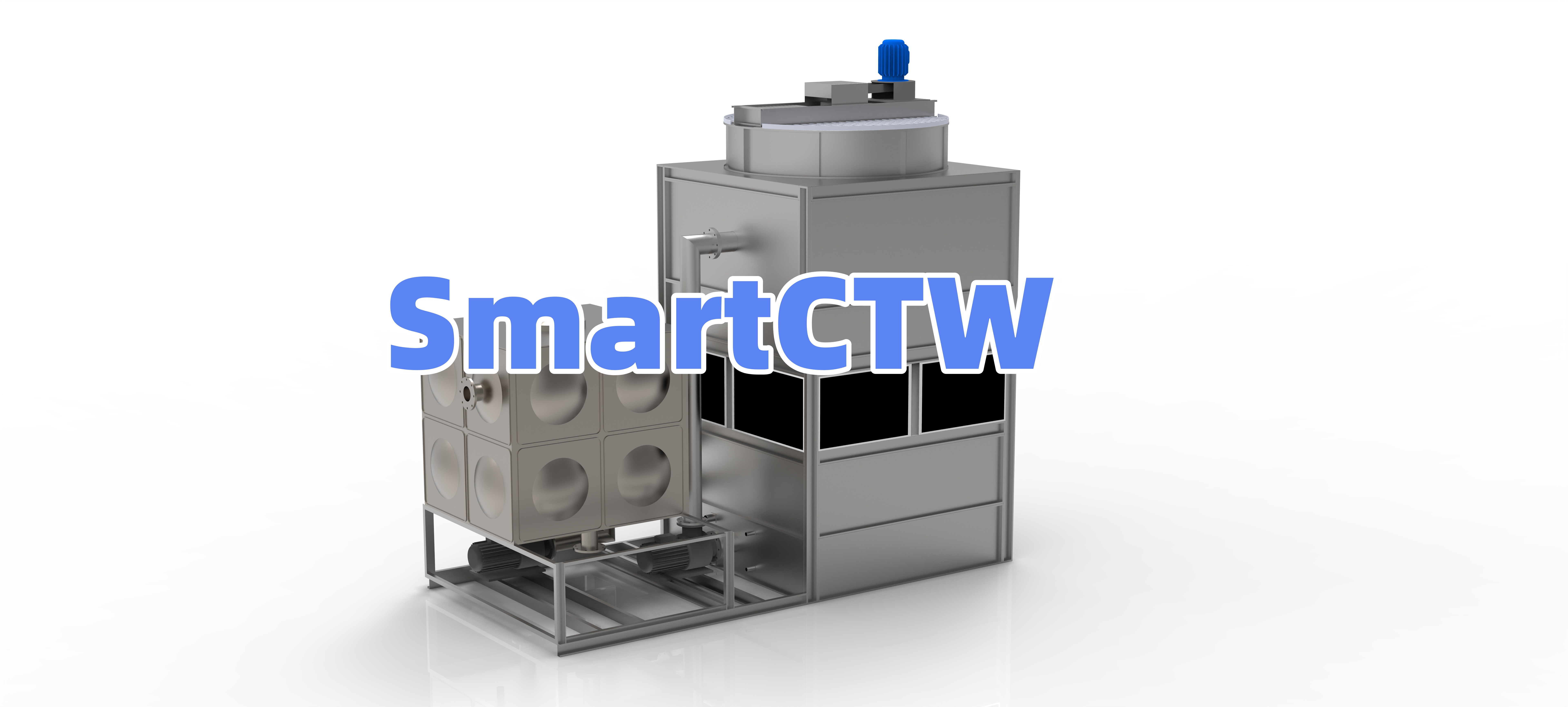

1. Tower shell

The main material for cooling tower production is magnesium-aluminum-zinc steel plate (optional Z700 heavy galvanized steel plate, ordinary galvanized steel plate and SUS304 stainless steel plate), all of which are made of national standard materials without negative difference. Excellent anti-corrosion performance.

2. Frame and fasteners

The frame is made of high-quality high-strength hot-dip galvanized steel, and the structural design is reasonable to ensure the stability of the equipment while saving materials as much as possible.

The fasteners are SUS304 bolts, which have excellent anti-corrosion performance.

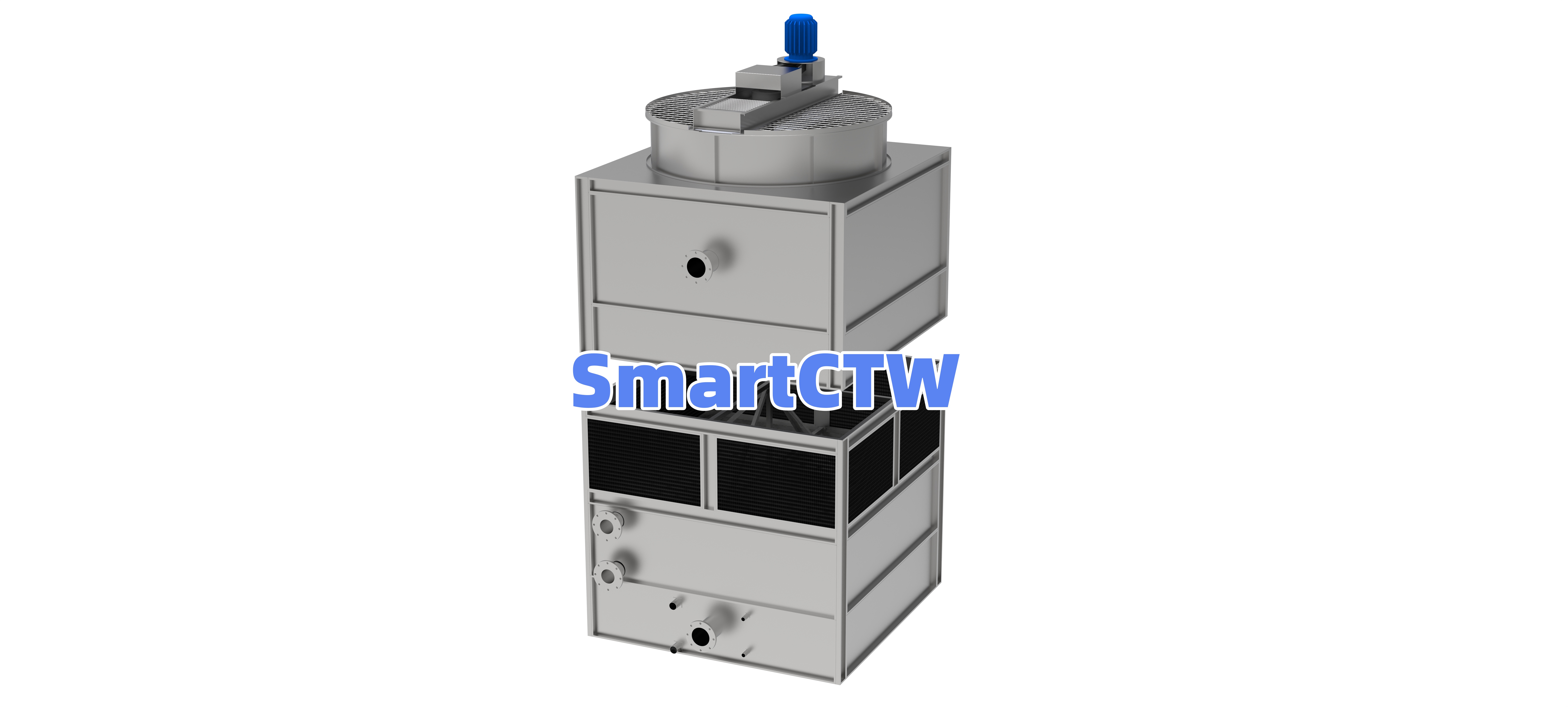

3. Fan

The fan adopts axial flow, and the fan blades are mostly hollow aluminum alloy airfoil. The fan blade angle is adjustable, and dynamic balance test is performed before leaving the factory.

4. Fan motor

The fully enclosed cooling tower special waterproof motor is adopted, which is maintenance-free except for normal refueling, reducing customer use and maintenance costs.

Before the motor leaves the factory, our company's self-developed refueling equipment will be installed to make motor refueling more convenient.

5. Heat exchange coil

Standard SUS304 material, high cost performance, strong corrosion resistance, long service life, the assembled coil is tested in water at 1.0MPa 9 air pressure to ensure no leakage, you can also choose copper tube titanium tube or SUS316 coil according to customer requirements.

Heat exchange coil can be designed in multiple groups in parallel. When a group of coils has problems, you only need to close the valve to repair it without stopping the machine.

The coil is installed with a certain tilt angle, which is conducive to emptying.

6. Spray water pump

Select a special spray pump for cooling tower, which has the characteristics of low head, large flow, low power and low noise.

7. Air inlet grille

According to different use occasions, the air inlet grille made of PVC or magnesium-aluminum-zinc plate has low wind resistance, prevents direct sunlight, prevents algae reproduction, breeds microorganisms, and prevents drifting water.

8. Water collection tank

The material is Z700 heavy galvanized plate, which has strong corrosion resistance and longer service life. A deepened water collection tank is used to ensure the adequacy of the spray water. Solenoid valves, liquid level sensors, and automatic water replenishment can be equipped as required.

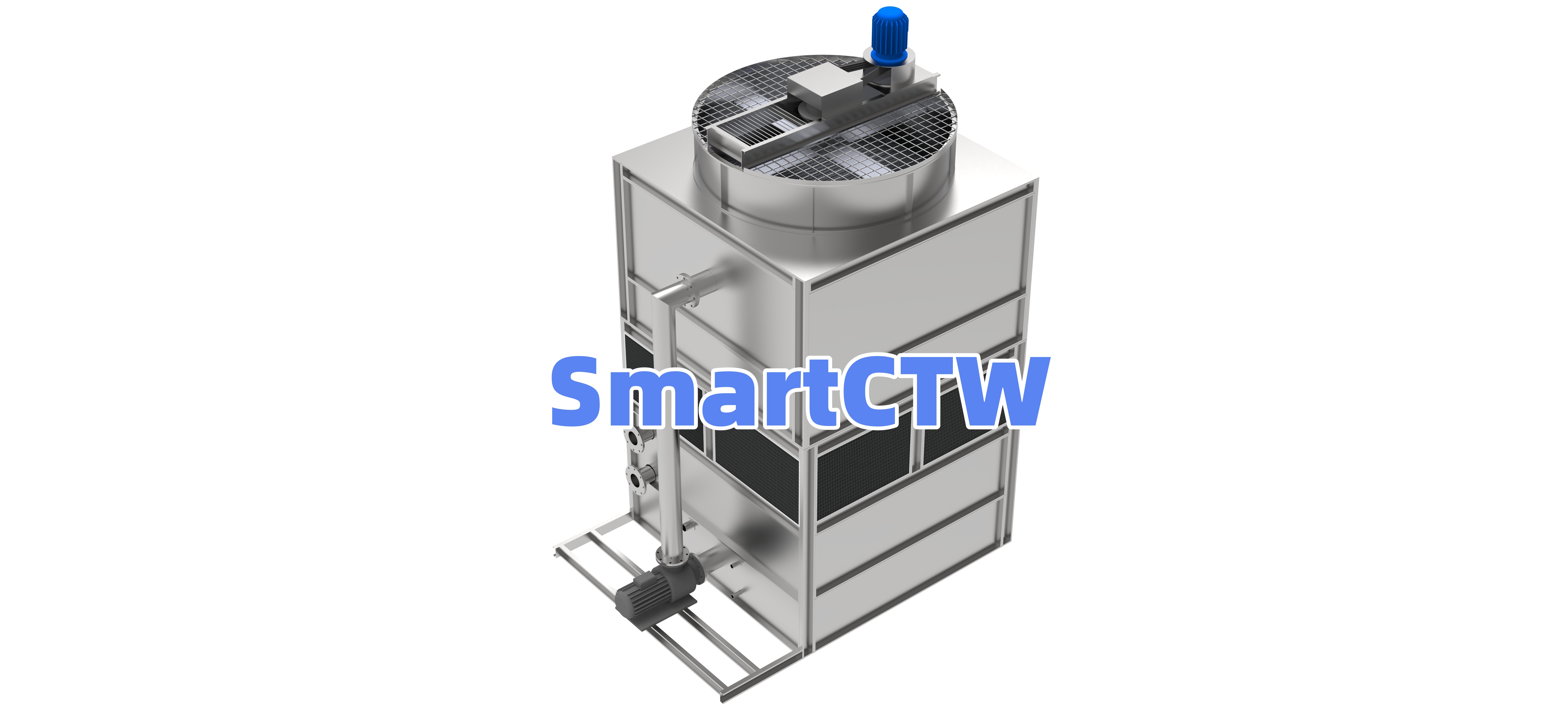

9. Float valve

It can replenish the loss of cooling water evaporation. It is equipped with an automatic water replenishment device, all stainless steel, and a four-link mechanism, which is convenient and flexible.

10. Double water distribution system

It adopts a large-flow three-splash or variable-flow nozzle with large flow, no blockage, and no dead corners. The double water distribution system can effectively ensure that the spray water is evenly distributed on the surface of the filler and heat exchange tube.

11. Electric heater (optional)

When operating in winter, the electric heater can be turned on to prevent the heat exchange coil and water collection tank from freezing.

9. Intelligent control (optional)

The cooling tower integrates automatic control, operation status display, protection, and alarm light functions, and can be connected to the BA system, which can realize remote viewing and control of fans and water pumps, liquid level detection and automatic adjustment in the water collection tank, and automatic control of the water collection tank antifreeze electric heater.