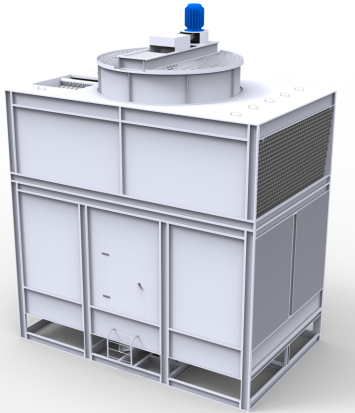

1.Enclosure structure

The main material for cooling tower production is magnesium-aluminum-zinc steel plate (optional Z700 heavy galvanized steel plate, ordinary galvanized steel plate and SUS304 stainless steel plate), all of which are made of national standard materials without negative difference. Excellent anti-corrosion performance.

2. Inspection door and inspection passage

The oversized inspection door is used to make it more convenient for personnel to enter and exit. The inspection passage is set inside the tower to facilitate personnel to inspect the inside of the cooling tower.

3. Skeleton structure

The frame is made of high-quality high-strength hot-dip galvanized steel, with an overall column design, supplemented by reasonably arranged beams and inclined installations to enhance the stability of the tower structure. The design of the long-span beam has been calculated in detail by professional designers and verified by physical models, and the deflection values of the entire series are controlled within the standard reliable range.

4. Axial flow fan

The wing-shaped fan blades are used, and the dynamic and static balance tests are performed before leaving the factory. The fan adopts a large air volume design, the fan blade angle is adjustable, and the fan noise meets the national standard noise requirements.

5. Fan motor

Use a fully enclosed waterproof motor for cooling towers, which is maintenance-free except for normal refueling, reducing customer use and maintenance costs.

Before the motor leaves the factory, our company's self-developed refueling equipment will be installed to make motor refueling more convenient.

Provide a variety of motor models to meet customer requirements under different working conditions, including dual-speed motors, variable frequency motors, explosion-proof motors, etc.

6. Transmission method

Use belt or gear reducer combination of traditional, low cost of wear parts, low use and maintenance costs. The reducer has high manufacturing precision, high transmission efficiency, low noise, long effective use period of equipment, and convenient maintenance and repair.

7. Heat exchange coil

Standard SUS304 material, high cost performance, strong corrosion resistance, long service life, the assembled coil is tested in water at 1.0MPa 9 air pressure to ensure no leakage, and copper tube, titanium tube or SUS316 coil can also be selected according to customer requirements.

The coil is designed with an inclined angle when installed for easy emptying.

8. Anti-drifting measures

Install a water collector in the air inlet area, and the wind speed in the tower is strictly designed according to the optimal economic wind speed, which can effectively avoid the "splashing" of the spray water and reduce drifting.

9. Water distribution system

Use a large-flow three-splash or spiral nozzle, with large flow, no blockage, and no dead corners, which can effectively ensure the uniformity of water distribution.

10. Transportation and installation

Use upper and lower split transportation, and tower body combined installation, which is convenient for replacement and maintenance, and reduces assembly and on-site construction time.

9. Intelligent control (optional)

The cooling tower integrates automatic control, operation status display, protection, and alarm light functions, and can be connected to the BA system to remotely view and control the operation status of the fan and water pump.