SmartCTW Cooling Tower Operation Preparation and Maintenance - Cold Water Basin

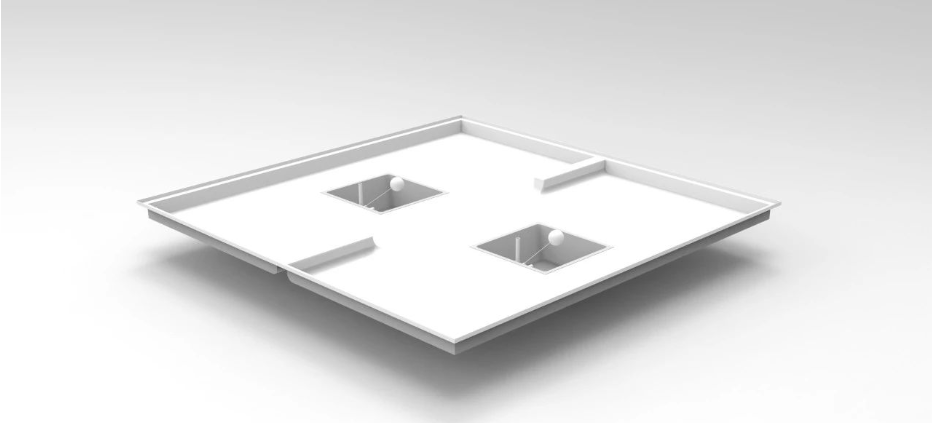

Points: The function of the cooling tower water collection pan is to recycle the cooling water after cooling and return it to the cold water system. The depth of the water pan should be designed according to the cooling water shutdown stagnation retention, that is, the water pipe retention + cooling tower retention < cooling tower water pan maximum water storage - water pan normal operation water volume, to meet the requirement of no overflow of cooling water after shutdown.

Inspection points and maintenance requirements:

1. Clean the cold water pan and check the use of the scale inhibitor: After a refrigeration cycle, the water pan will deposit sand, rust residue in the circulation system and other dirt, which needs to be cleaned manually regularly; the protective net in the outlet pipe groove needs to be removed and cleaned to prevent blockage and poor water flow.

2. Leakage inspection and repair measures: After confirming the leakage point, it needs to be marked. FRP glass fiber reinforced steel structure tower is sealed with sealing materials such as resin, glass fiber or butyl rubber strips; steel structure cooling tower needs to be reinforced with rubber strips for secondary reinforcement.

3. Check the water supply valve: Check whether the water level of the float water supply is normal and whether the mechanical structure is operating normally; if there is uninterrupted water supply or no water supply, the float valve must be replaced or repaired in time.

A total of 1 page 1 data