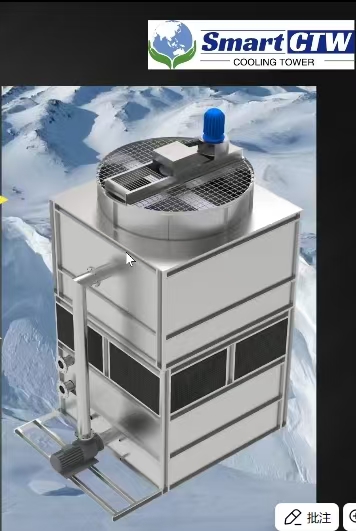

In the hot summer, SmartCTW cooling tower operation preparation and maintenance - transmission system

Enjoy the coolness, the air conditioning water system has entered the preparation stage, and the maintenance of the cooling tower should also be carried out simultaneously! SmartCTW takes you to understand the maintenance of cooling towers.

Points: Maintenance of cooling tower transmission system

1. The cooling tower motor usually adopts the IP55 protection level of the shell, F-level insulation, B-level temperature rise, 30-50HZ wide-band variable frequency speed regulation waterproof motor; before entering the cooling season, check in advance whether the motor has a stuck problem, and fill the motor bearing with lubricating oil for maintenance. After operation, check the lubrication condition regularly and keep daily maintenance records.

2. Check the windmill to see if there is any collision damage caused by the last cooling cycle, check whether the U-shaped fastening screws are loose, and whether the fan angle is consistent; if the fan vibrates, makes abnormal noises, loses rotation after the trial operation, or the motor current does not reach more than 90% of the rated power, ask our after-sales staff for evaluation and maintenance adjustment.

3. Lubricate the reducer bearings with oil (if a gear reducer is used, the lubricant should be replaced according to the lubricant's quality assurance cycle); for belt reducers, the belt wear condition should be observed and replaced in time. If the belt is too loose or too tight, it should be adjusted in time.

A total of 1 page 1 data