Indonesia Metal Processing Production Park Project

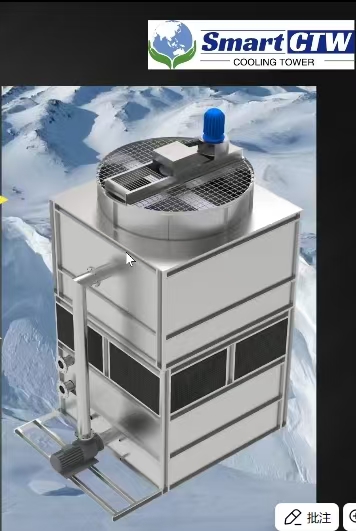

This project has a short delivery period. It is necessary to produce customized cooling towers, a full set of water treatment pump room equipment units, integrated automation instrument control, and pump groups based on the foundation that has been made on site. All electromagnetic shielding is required.

The full set of equipment systems are prefabricated in the workshop, and welding is not allowed on site. The stainless steel surface of the cabinet is all brushed stainless steel. All line ducts are prefabricated in the factory.

Material requirements: The shell and frame are all made of 3-5mm SUS304 stainless steel, and the heat exchanger is made of 316L thickened raw materials. All pipelines are made of 304 stainless steel. All components such as the integrated pump room are made of 304 stainless steel. The tower top guardrail is required to use zebra pattern warning.

A total of 1 page 1 data