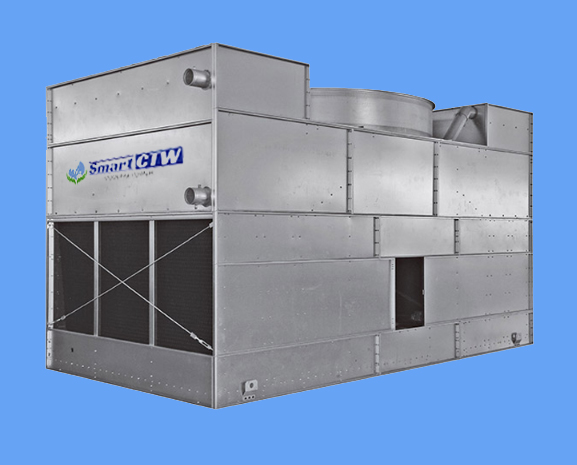

1. Reasonable structural design

The company's technical personnel have been engaged in the leading enterprises in this industry for more than 30 years, and have rich theoretical and practical experience. They have rationalized the design of the tower structure. Ensure the stability and efficiency of equipment operation.

2. Stable thermal performance

Thermal performance is the most important performance indicator of the cooling tower. Our company has a strict management process from design, production, installation, and commissioning to ensure that the thermal performance of the cooling tower can meet the requirements. Customers do not have to worry about the normal operation of the entire production process due to insufficient thermal performance of the cooling tower.

3. Long service life

The tower panel is made of all-steel, the tower structure is made of high-strength hot-dip galvanized material, the water tray is made of Z700 heavy galvanized material, and the heat exchange coil is made of stainless steel. The overall anti-corrosion performance of the equipment is excellent, and the use and maintenance costs are low.

4. Short production period

The company's cooling tower adopts modular design, standardized, universal, and automated production, which greatly improves the efficiency of the entire process, shortens the equipment production period, achieves high-quality and rapid delivery, and ensures the quality of the product. The equipment operation is more stable and reliable.

5. Factory assembly, overall/module delivery

Our company will arrange the delivery of integrated machines or modules according to the size of the cooling tower equipment. The on-site work volume is very small, which can maximize the high-quality control, greatly improve work efficiency, reduce product delivery cycle, and be safer, more time-saving, more environmentally friendly, and more reliable.

6. Energy saving and consumption reduction

The cooling tower optimizes the cooling coil, filler, water distribution system, fan and air flow and water flow distribution in the tower through reasonable design and computer simulation, which can significantly reduce energy consumption while maintaining efficient cooling performance, and achieve the goal of energy saving and consumption reduction.

7. Convenient maintenance and repair

The use of enlarged inspection doors makes it more convenient for personnel to enter and exit. The tower is equipped with an inspection channel. The status of the air system and the spray water system can be checked when the equipment is running, and the coil can be checked without stopping the machine to ensure long-term and efficient cooling of the product.