Introduction to the main production process of cooling tower

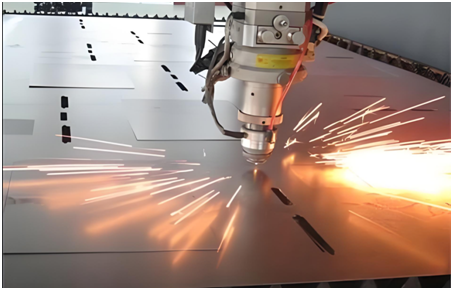

1. Laser cutting: Instead of welding and galvanizing steel sections in traditional cooling tower production, laser cutting is used to directly obtain materials, forming them in one step without burrs or welding slag. Metal sheets do not need to be galvanized again, so the appearance is exquisite.

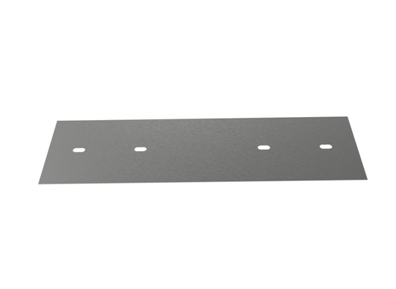

2. CNC bending: Bending is to bend cold metal sheets into workpieces of various geometric cross-section shapes using the equipped molds (general or special molds). The bending machine generally uses a special CNC system for the bending machine, which can automatically realize the slider running depth control, slider left and right tilt adjustment, rear stopper front and back adjustment, left and right adjustment, pressure tonnage adjustment and slider approach working speed adjustment, etc. The bending machine can easily realize the slider downward, inching, continuous, pressure holding, return and midway stop movements, and complete the bending of multiple elbows at the same or different angles with one loading

Factory production process

A total of 1 page 1 data